Search This Supplers Products:Glass perfume bottlePlastic perfume capAluminium perfume capZamac perfume capWooden perfume capPerfume pump sprayer

special turquoise zamac perfume bottle caps manufacturers | zinc alloy perfume cap | GP Bottles OEM ODM Manufacturing

- group name

- Zamac perfume caps

- Min Order

- 10000 piece

- brand name

- GPBottles Perfume Packaging Manufacturer

- model

- GP-3010ZC

- Nearest port for product export

- Shanghai, Ningbo, Shenzhen, Qingdao

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FCA, DDP, DDU, Express Delivery

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Westem Union, Cash

- update time

- Thu, 25 Dec 2025 07:46:41 GMT

Paramtents

Material zamac

Decoration Vaccum plating

Neck FEA 15

Weight 60g

Packging & Delivery

-

Min Order10000 piece

Briefing

Custom zamac perfume cap for glass bottle standard quality with kinds of decorations

Detailed

Complete Perfume Packaging Solutions - GP Bottles

Wholesale perfume cap: with the advantage of weighty, solid, qualited, zinc alloy cap have been used more and more for luxury perfume brand. GP Bottles design and manufacture high quality zinc alloy perfume cap with OEM ODM service for our global partners.

Technical Parameters

|

Model no.

|

GP-3010ZC

|

|

|

Material

|

Zinc alloy / Zamac

|

|

|

Decoration

|

Vaccum plating / electropalting

|

|

|

Color

|

Gold, silver, pink, green or others

|

|

|

Weight

|

60 g

|

|

|

Dimensions

|

Φ29.5 x H 32mm

|

|

|

Neck

|

FEA 15

|

|

Packaging | Master Carton | |

Qty/Ctn | 160 pcs | |

Carton size | 43x27x15 cm | |

Gross weight | 11.0 Kgs | |

20' container load | 240,000 pcs | |

40'container load | 510,000 pcs | |

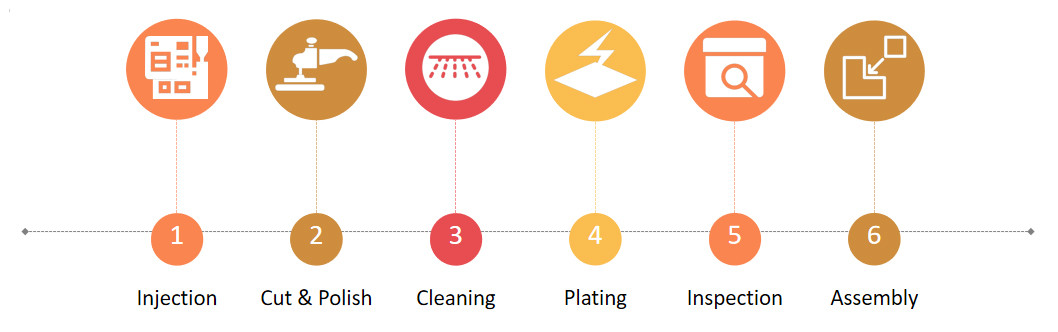

Processing

Tooling process

Precise tooling process to make sure the quality of dimension, fixing and surface.

Finishing process

Kinds of finishing process like laser logo, vaccum plating, electroplating, drip print, silk print etc.